Machining Inconel 718 With Ceramic Tools

Top 7 tips on machining inconel hastelloy monel and other nickel alloys.

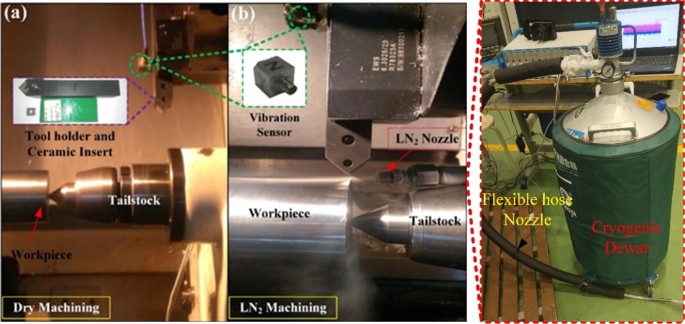

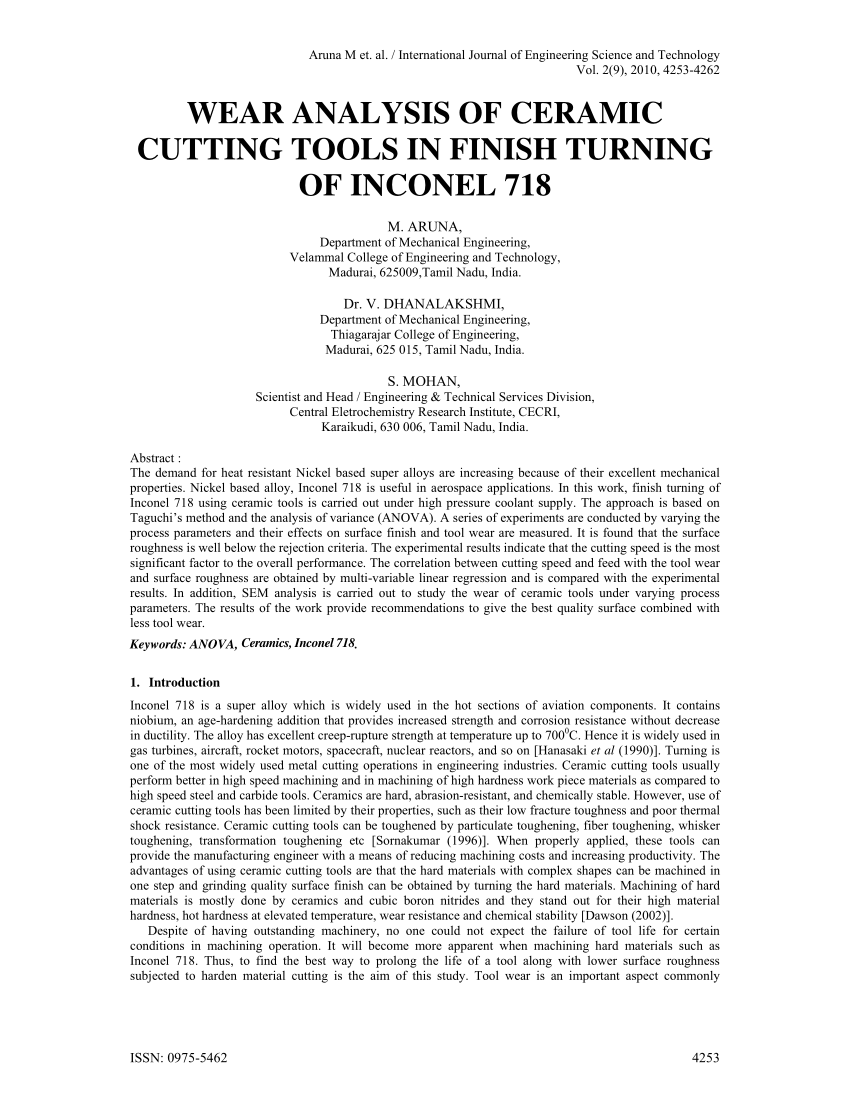

Machining inconel 718 with ceramic tools. It can be considered that the notch wear at the depth of cut line when machining inconel 718 is a kind of transfer type wear generated by an adhesion of work material to the. This reduces the wear and tear placed on machining tools. Starting with a solutionized piece of inconel is optimal because it helps to limit the amount of work hardening. Pushing the envelope with inconel machining.

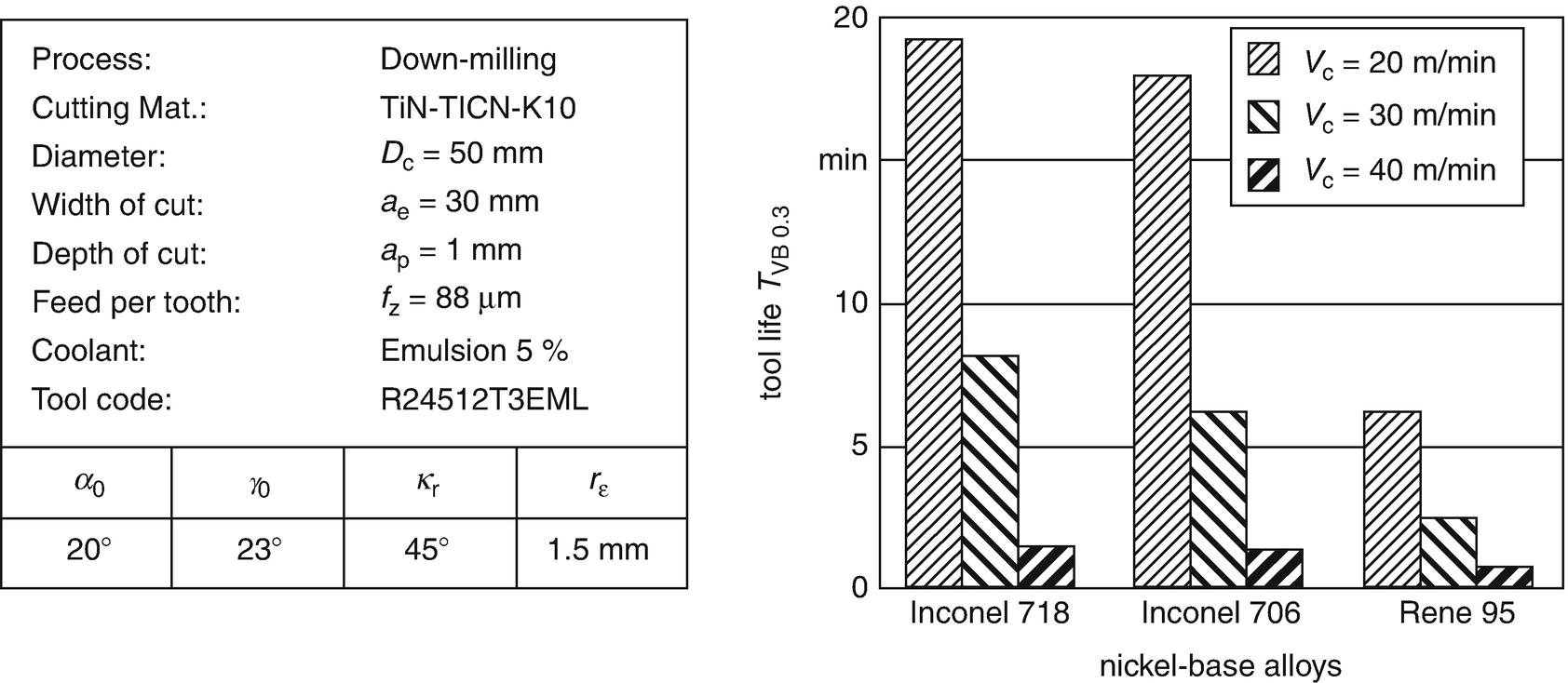

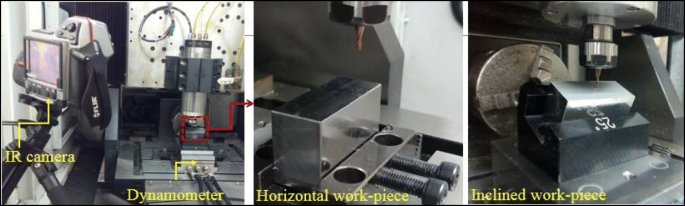

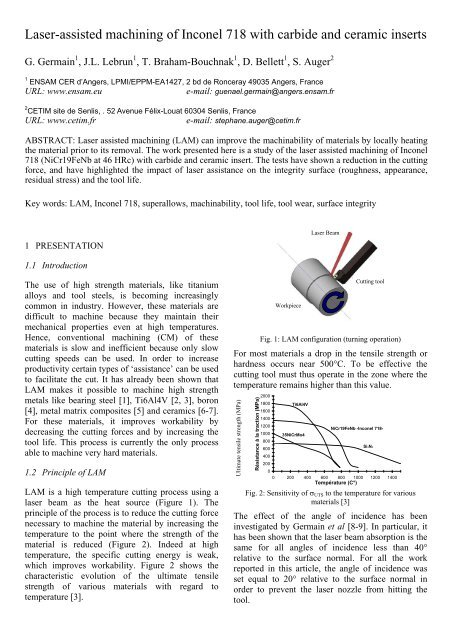

With an ingersoll ceramic insert some creative toolpath programming extra attention to heat management and a willingness to burn through inserts to maximize throughput the busy ball turning operation has quadrupled throughput. Cnc machining is what we do. Wear rate of ceramic tools at high cutting speeds is smaller than those cutting tools at low cutting speeds. Furthermore as for the si3n4 ceramic tool it can be seen that si in the tool diffuses into inconel 718 and cr in the alloy has 104 be observed according to these points.

Lower cutting forces were recorded with increasing coolant supply pressure when machining inconel 718 with sic whisker reinforced alumina ceramic tool. These are great tools for production parts when a statistical analysis of tooling cost vs labor can be made. 19 while machining inconel 718 used ceramic and carbide tools and compared their performance in terms of roughness and cutting forces. In some literature studies whisker reinforced aluminum oxide cutting tools are suitable for the machining of inconel 718 at the cutting speeds between 200 m min and 750 m min.

Being able to make a fast continuous cut is important for minimizing the risk of work hardening mid process. We are experts and on this channel we are bringing our knowledge and. Ceramic turning and ceramic milling drastically increases metal removal rate in roughing operations but requires experience. It is recommended that ceramic cutting tools be used when working high nickel alloys in order to achieve long uninterrupted cuts.

Cnc machining inconel 718 with kennametal ceramic endmills. Use ceramic cutting tools for continuous cuts. Ceramics are not the right tool. Avoid peck drilling with inconel in machining pecking is a drilling process of repeatedly inserting the drill bit part way into the material and retracting until the hole is finished.