Ltcc Ceramic Powder

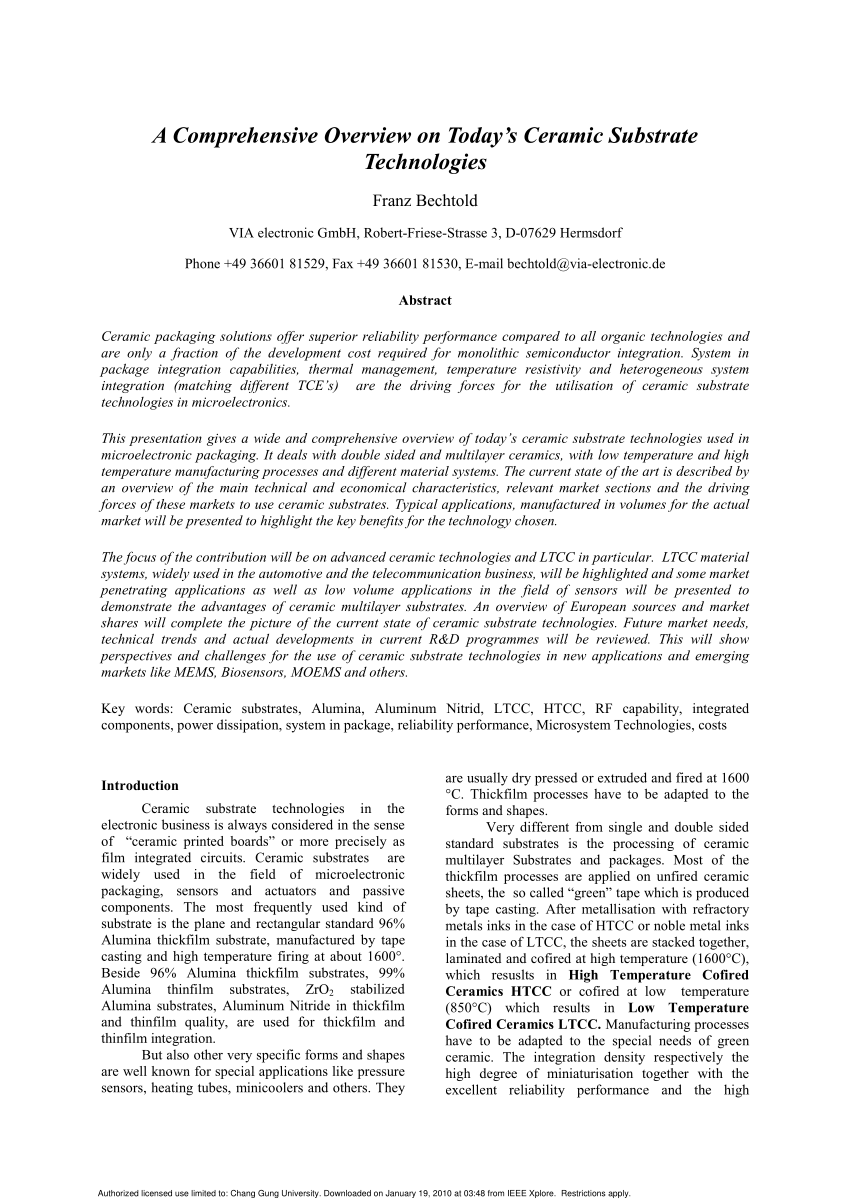

It is sometimes referred to as glass ceramics because its composition consists of glass and aluminum.

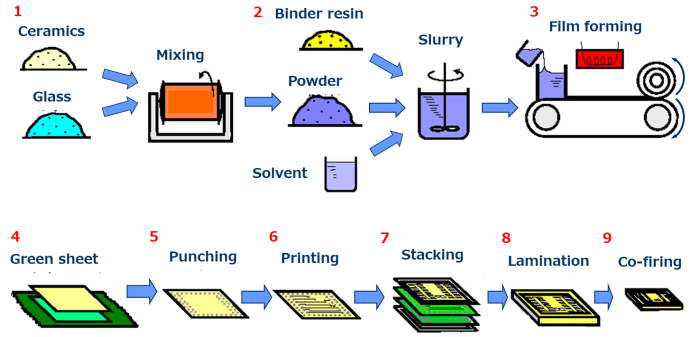

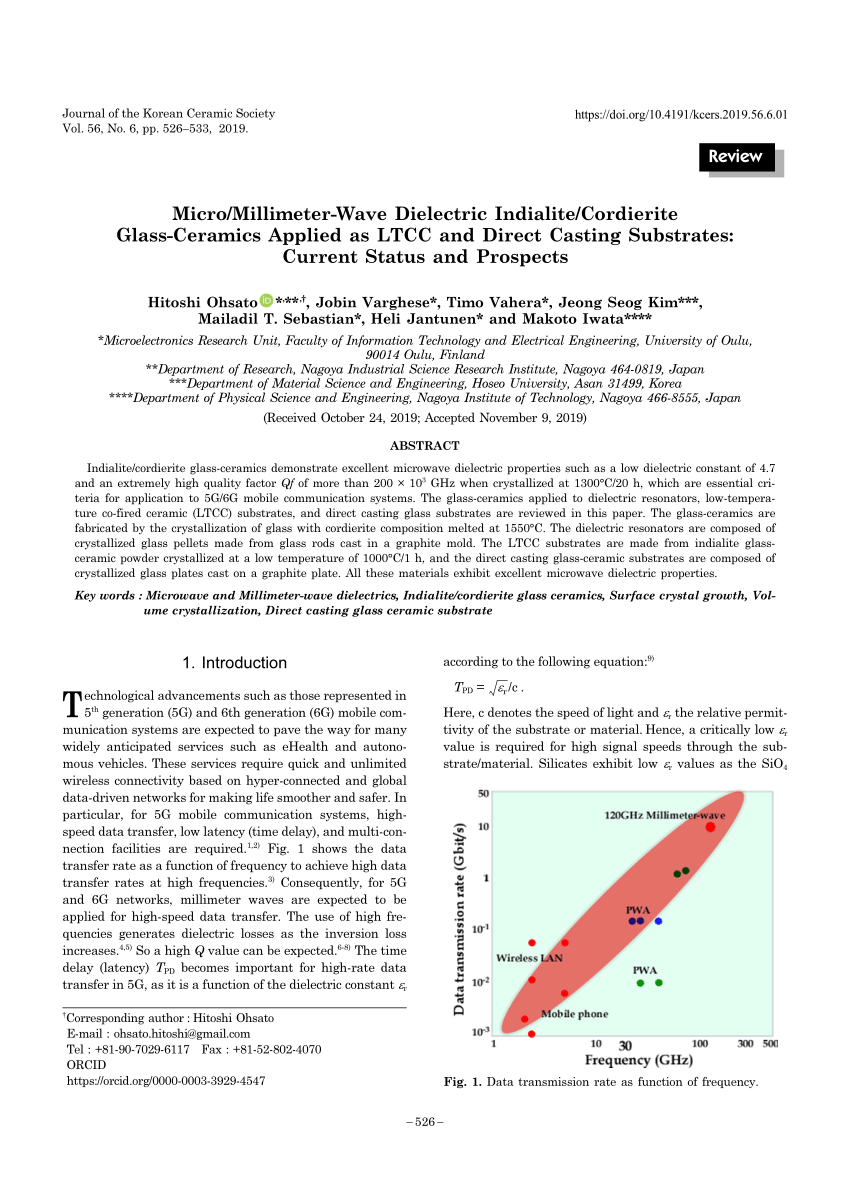

Ltcc ceramic powder. The dupont greentape 951 low temperature co fired ceramic ltcc material system combines the benefits of multilayer co fired ceramic and thick film technologies to meet the increasing demand for reliable electronics functioning in extreme heat and other harsh environments. Into a multilayered ceramic module by interconnecting each component in layers. The particle diameter of ferrite powder was about 300 nm. Ltcc low temperature co fire ceramics is a multi layer glass ceramic substrate which is co fired with low resistance metal conductors at low firing temperature less than 1000.

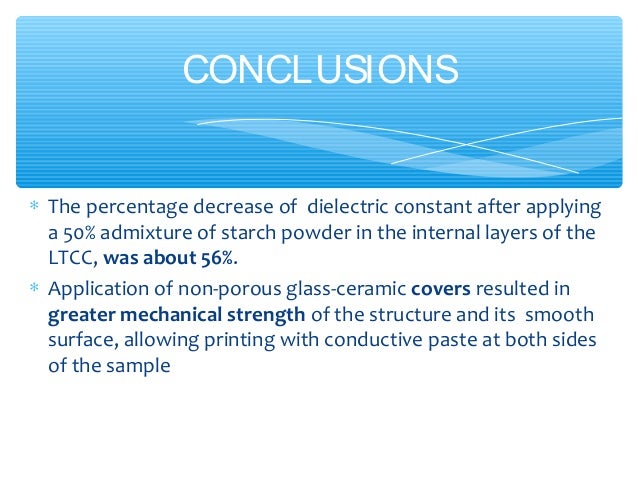

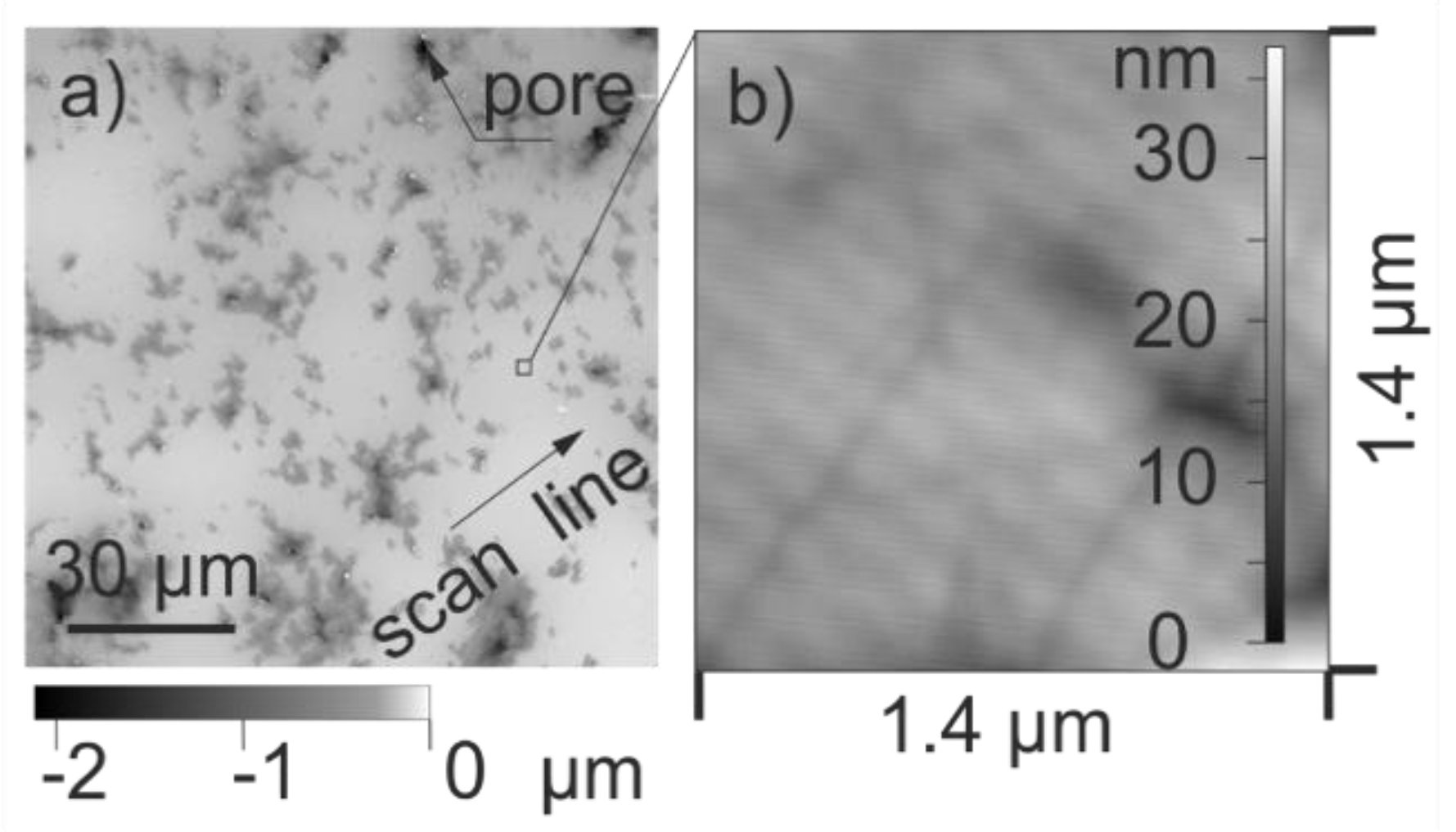

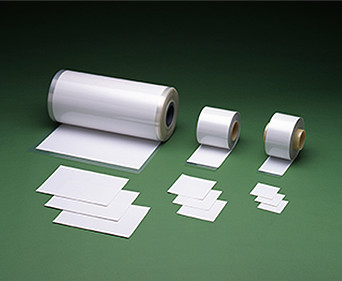

The ceramic sintered at 785 c for 2 h exhibits excellent dielectric properties of ϵ r 2 86 q f 38093 ghz 16 0 ghz τ ƒ 2 17 ppm c which indicates that the ceramic is a promising candidate for ltcc applications. Ltcc sheet in unfired sometimes called green state is a thin flexible compound of ceramic or glass powder with organic composites. Composite powder for low temperature cofired ceramics is a composite material that is made by uniformly blending glass and ceramic fillers. The composite weight ratio of the glass powder and the alumina powder in the glass alumina composite material was 63 and 37.

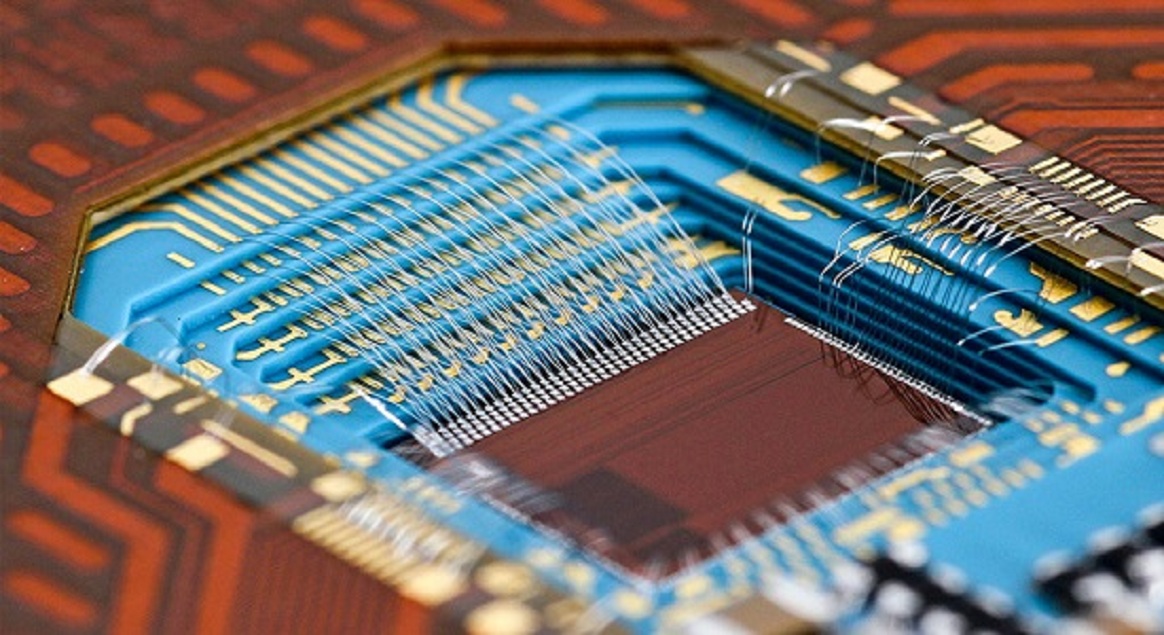

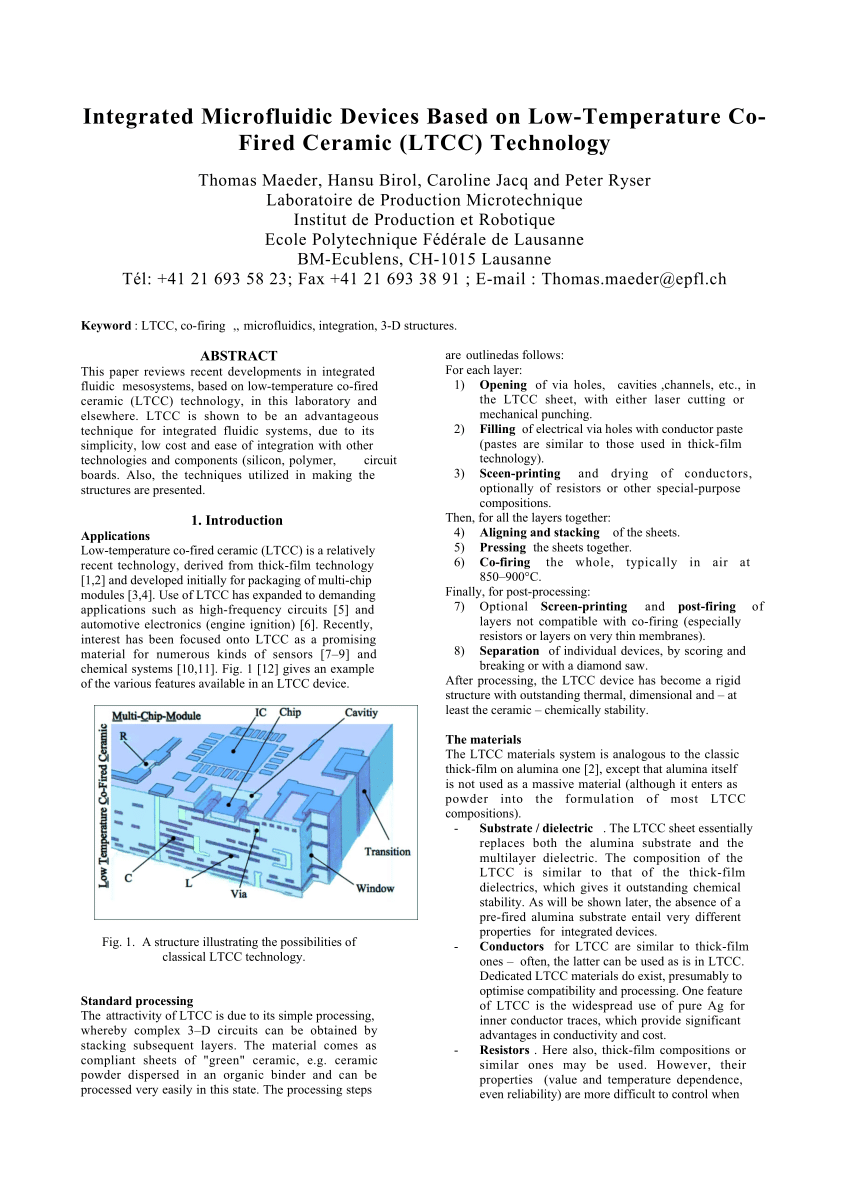

A low temperature co fired ceramic ltcc device is one of the most rapidly developed integral passive devices which provides a solution to the integration of passive components such as capacitor resistor inductor resonator and filter etc. Chip filter chip antenna chip inductor capacitor high k er 40 low k er 8 rf smd component with 3 component design patents rn2 designs and manufactures rf smd components for amp rrh. Ferro offers ltcc glass ceramic powder formulations with a wide range of k values for use in a variety of components across a vast range of frequencies. Firing can be conducted at a low temperature in the range of 870 900 c which allows the use of highly conductive elements such as gold and silver paste to create a screen print circuit pattern with high electric properties.

In order to allow the co firing of metals with high electrical conductivity the sintering temperature of the ceramic substrate has to be reduced well below the melting point of the individual metal e g.