Light Gauge Metal Framing Wall Advantages And Disadvantages

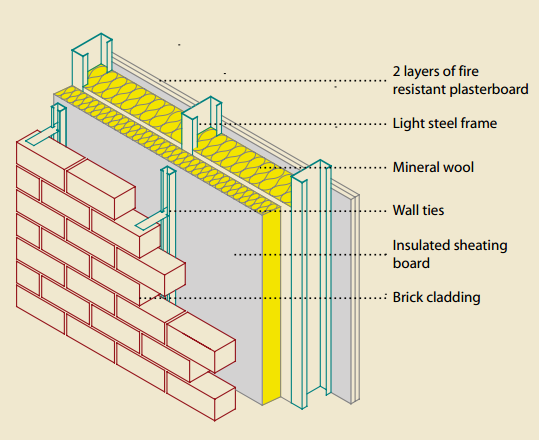

Exterior cladding consist of a single skin wall or fiber.

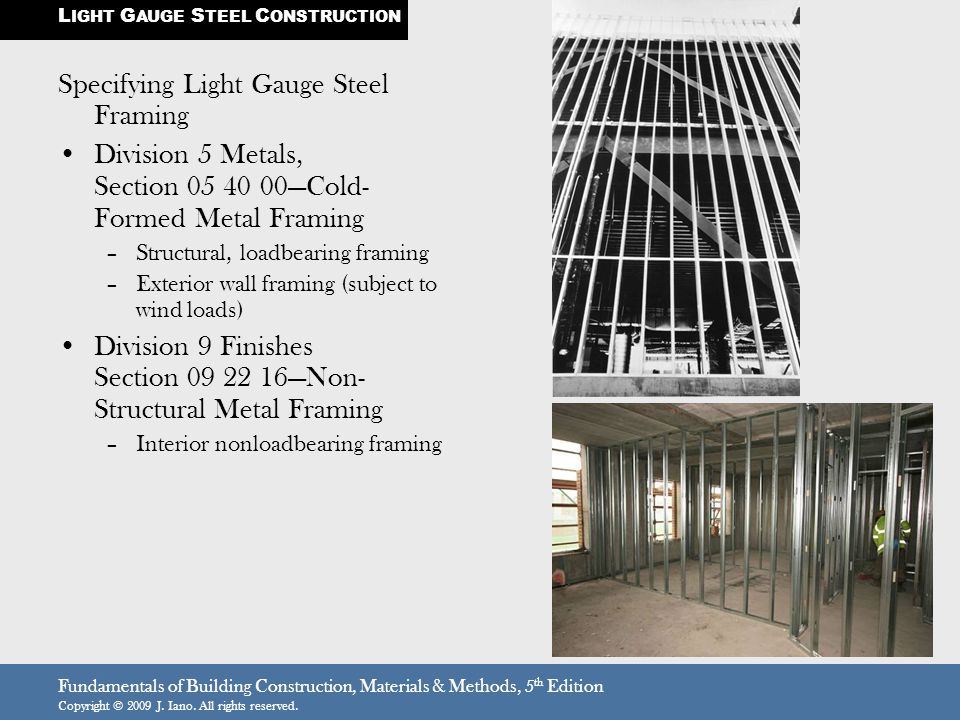

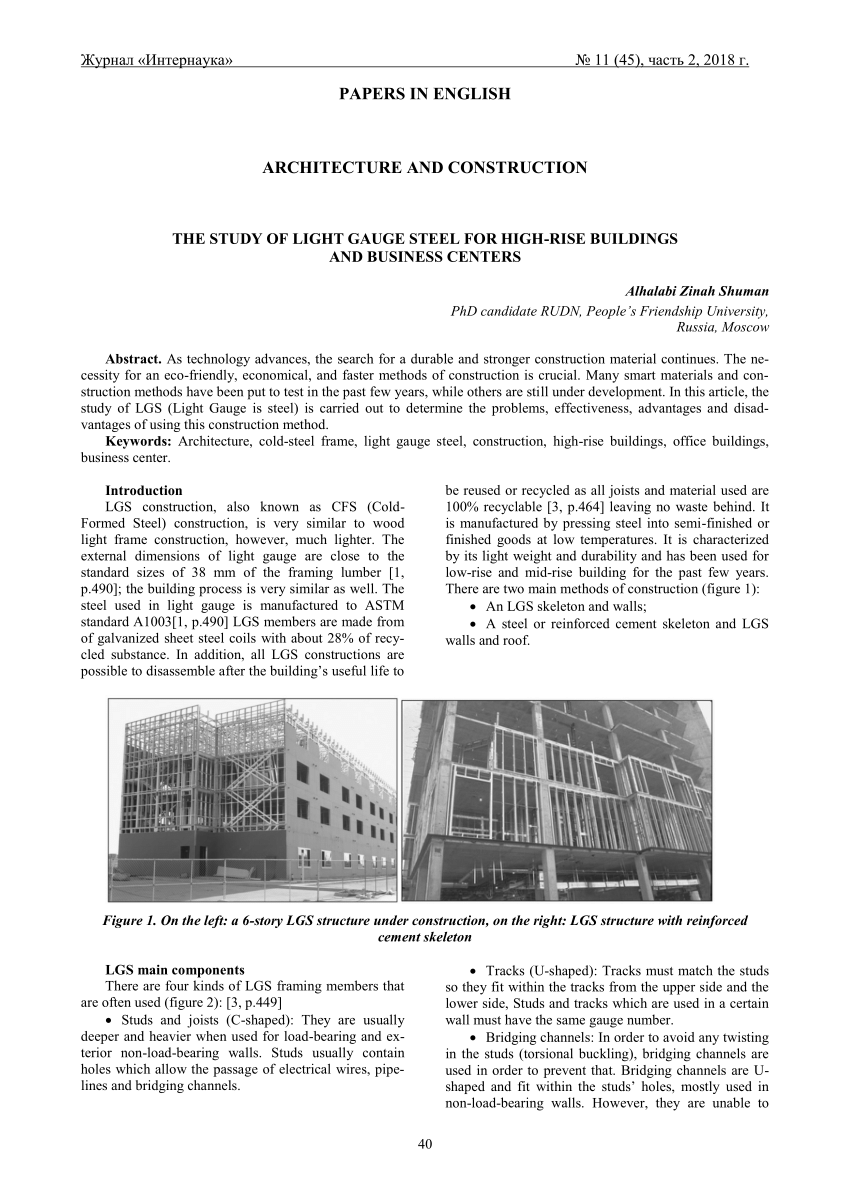

Light gauge metal framing wall advantages and disadvantages. Lgs takes less construction time with comparison to bricks or concrete blocks construction. The strength of light gauge steel frames permit longer spans larger open spaces without the need for intermediate columns or load bearing walls. As a metal light gauge steel won t rot split warp shrink twist burn or become termite food. Steel is easy to manufacture and is frequently made from recycled material which cuts both the environmental impact and the cost to the consumer.

The advantages of light gauge steel construction are listed below. Environmental advantages and disadvantages steel studs are 100 recyclable and light gauge steel framing has about 20 25 recycled content. It overall saves up to 30 time for a project. Light gauge steel will lose strength in the advent of fire.

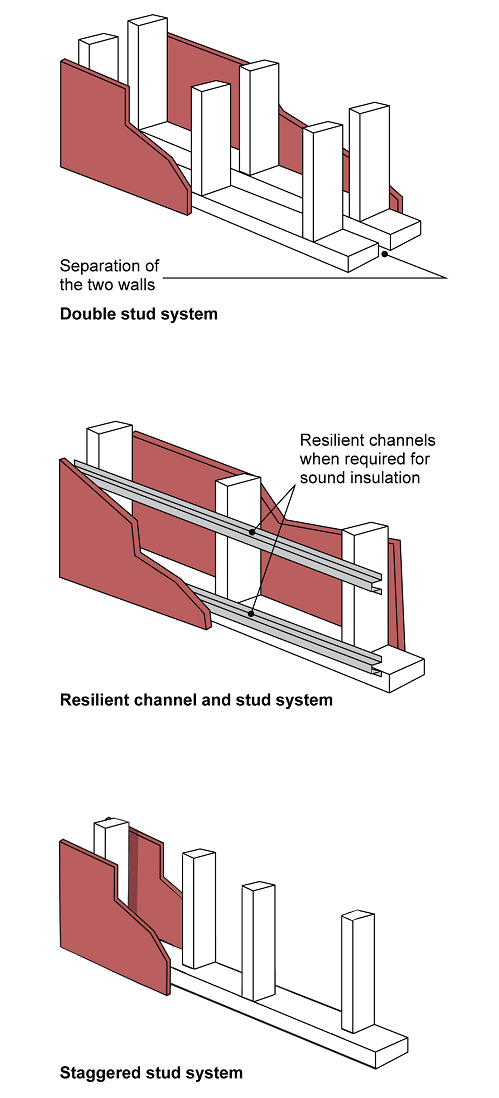

Metal framing is not as strong as wood another drawback when framing with metal is the overall strength of light gauge galvanized steel. The structural steel frame can be erected quickly since the structural members are prefabricated and can be easily handled due to their lightweight. Pros light gauge steel frames are assembled in a similar manner to wood platform framing and have some of the same advantages. Disadvantages of light gauge steel construction light framed structures allow the passage of sound more readily than the more solid masonry construction.

Adequate fire protection must be used. While it will maintain structural integrity metal. Cladding walls can be filled with a concrete mix which we call the solid wall services electricity and plumbing are installed in the wall cavity created on light steel studs as it happens with the insulation material. Steel framing produces far less on site waste than wood framing making debris removal less costly.

So the advantages and the disadvantages listed in this page for steel framing has a background the wood frame construction. The usage of light gauge steel structures lessens on field works decreases material wastage and enhances the quality of the structure. The longer spans means less fastening and faster construction.